Building stairs - a look at stair construction and layout

Building stairs begins with a stair layout and design that is easy for people to climb. The optimum rise and run of tread has been formalized by organizations such as the occupational health and safety association (OSHA). These specifications are widely used both inside and outside of the USA. Even though the elevation change required may vary from job to job, the stair designer can choose from a variety of stair tread designs

OSHA stairs are most commonly used in industrial applications where there is frequent need to climb up to the level of different equipment to take measurements, or read instruments or operate equipment. OSHA specs are also of practical use in the construction of cement and concrete stairs as well as wood and log stair construction in order to make a properly functioning safe set of stairs.

Baseline moving load for industrial stairs is 1000 lbs (1910.24c0)and the minimum width is 22 inches. The actual rise and run required varies based on the difference in elevations and the number of stairs. The angle of the stairs however must always be between 30 and 50 degrees. Stairs within these angles are considered safe and comfortable to use.

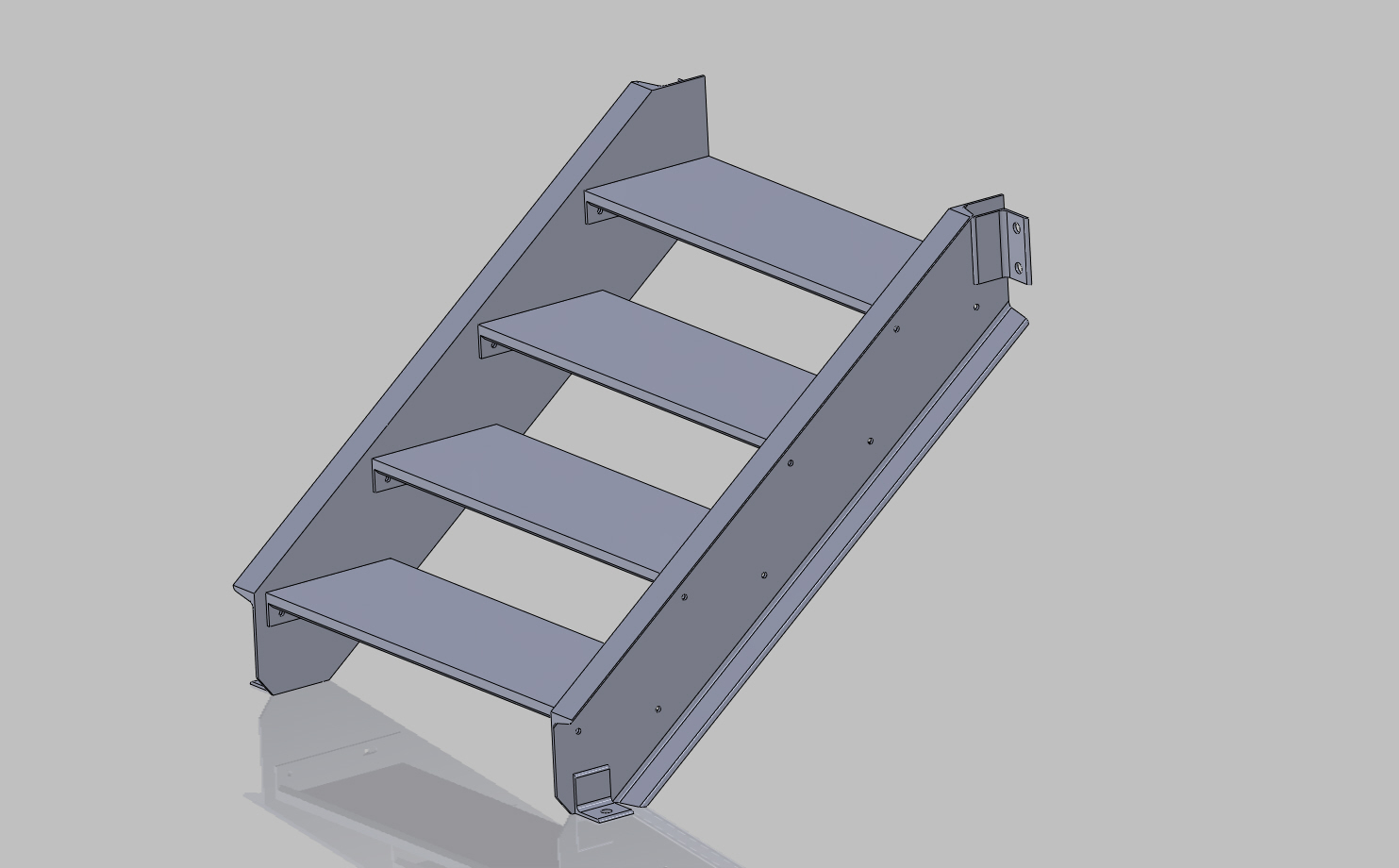

Stair Treads and Stringers modeled in 3D

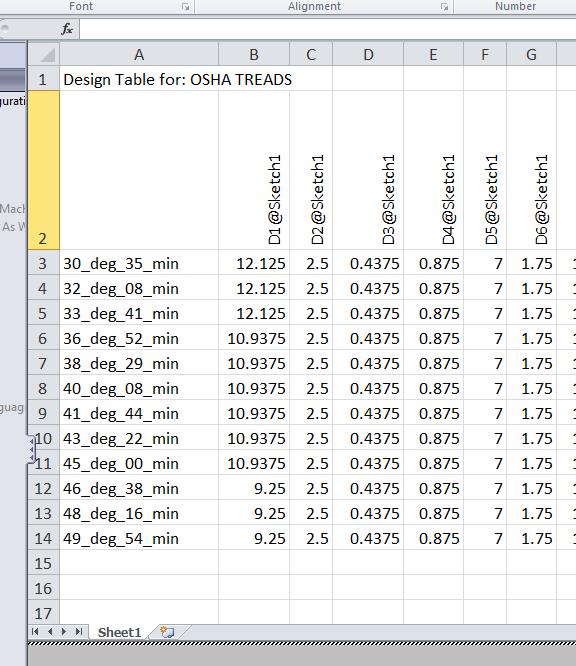

I have created a 3D model using commonly available stair treads and C channels for stair stringers. This model helps in building stairs through a design table which makes use of frequently used rise/run combinations for OSHA compliant stairs. The design table below shows stair tread rise and run between 30 and 50 degrees in 1/4" increments. The length of the stringer and the number of stairs is variable in order to accomodate the widest variety of elevation differences.

I also entered dimensions for the three commonly available tread width sizes from my local tread supplier. The model allows me to play with treads, stringers and different OSHA rise/run combinations to meet the desired change in elevations.

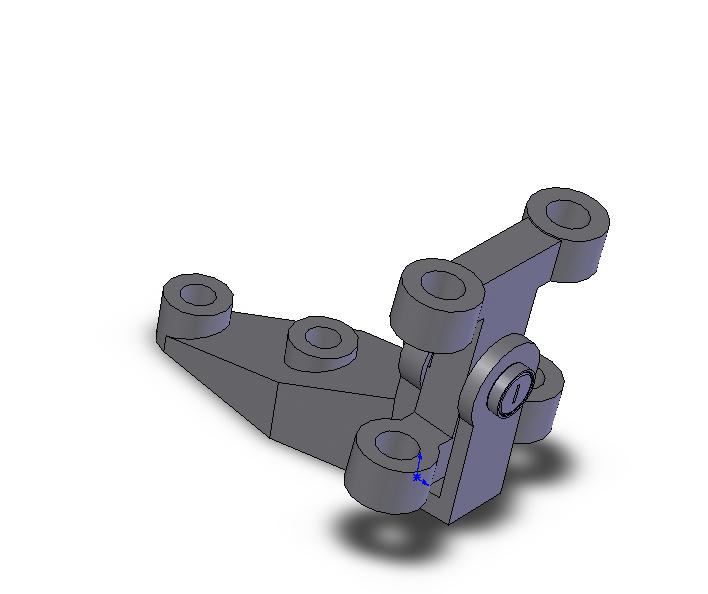

The metal stairs model also shows examples of mounting clips welded to the side of the stringer and bolted to the floor or other structures using structural grade bolts. The type of clips will vary based on the site conditions and company specifications.

In my stair building model I do not show nosings on the steel stair treads but OSHA requires checker plate nosings or at least a serrated grating bar marked with identifying paint. There should also be 7 feet of clearance above when going up and down the stairs. There cannot be any situations where you have to duck under an obstruction.

There should be at least one railing or handrail even if the stairs are closed on both sides by walls or structure. Railings must be used on all open sides of a stairway. Railings have to between 30 and 34 inches above the surface of each tread and constructed of material at least as strong as 2" x 2" x 3/8" L. A secondary railing must be placed half way between the top of the railing and the tread. On flet platforms the railing height rises to 42 inches.