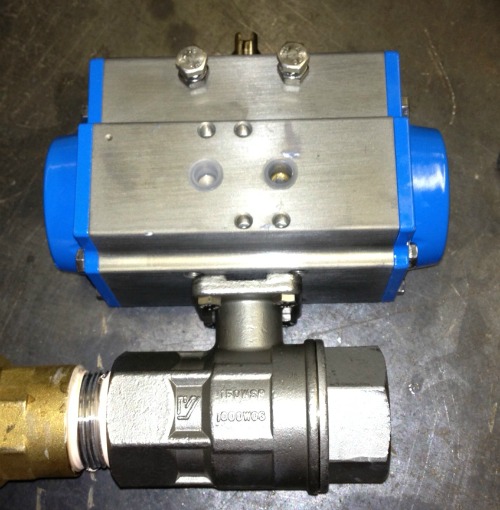

Pneumatic Actuator

This complete automated valve and pneumatic actuator assembly is ready for use, with 1 inch 2 way AISI 316 stainless steel ball valve, Female FNPT connections. The actuator requires Min 6 Bar (87 PSIG) air supply and is available with stainless valves in common imperial sizes such as 1/4", 3/8", 1/2", 3/4" and 1".

Hints and Tips

Typically we use 1/4" tubing with meter-in flow control valves to drive pneumatic actuator. The reasoning is that we dont need the ball valve closing too fast because the "water hammer" effect might damage sensitive downstream equipment like electronic flowmeters. The meter-in flow controls allow you to slowly open and close the valve. Unlike air cylinders where fast movement might be desirable

One caveat with using small tubing and small solenoid control valves is that they are more susceptible to dirty air. When we install these valve actuators we typically install 5 micron air filters on the supply line to the solenoid valves. This is in addition to the 40 micron filter used for the main air supply from the factory. Many customers supply air is often "dirty", especially those in the mining and paper industries.

In this picture the pin in the center of the top of the pneumatic actuator can be used to drive accessories such as a valve position indicator. The four tapped holes allow a place to attach the bracket for the position indicator. The two bolts on the front in the lower half of the picture control the limits of rotation for the valve. These seldom require any adjustment since the actuator is set up with its valve in the factory.

In the center of the picture you can see the two ports for the air connection. This is a single acting pneumatic actuator so one port is used to drive or turn the actuator, the same port is then used for exhaust when the air is turned off and the actuator spring pushes the valve back closed

If this were a double acting model, the physical appearance would be identical except that both ports would be used. One to open the valve and the other for exhaust. Then the reverse, the ports would be switched by a control valve so that the valve connected to the unit could be closed

The four tapped holes are used to attached control valves to the face of the actuator. This is more common when the actuator is installed in a pipe run.In situations such as pump skids the control valve is often located in a panel next to the PLC and other control equipment.

This particular unit was purchased complete with a one inch 316 stainless steel valve as a complete package. With small liquid valves, the actuators can bolt directly to the flange of the valve. With larger sizes it is necessary to put a bracket in between to create room a coupling to connect to the valve stem. The beauty of buying the the valve-actuator complete puts the onus on the supplier to deal with all the necessary brackets as well as the valve setup.

This valve-actuator is fine for use water but for solvents and hazardous liquids, you might need a different manufacturer if you have to provide TSSA certification. In Ontario, Canada there are seperate sets of regulations for the province of Ontario and for all Canadian provinces.