Part numbering and PDM systems

Part numbering back in the days of paper drawings, involved part numbers on various drawings. Very often this part number corresponded to a drawing number. To find everything you needed to know you simply looked up the drawing. It was possible that many drawings could be made with different part numbers showing the same part. The more designers there were making drawings, the more the possibility for duplicate parts with different numbers. Only a diligent engineering record keeper with a thorough knowledge of all the drawings could prevent this.

Nowadays we have 3D modeling systems that create separate files for the assembly and part and separate files for the drawing. They can and often do have the same part number. Now an army of diligent people are required to prevent same parts with different part numbers. Most 3d modeling systems let you name the parts, assemblies and drawings anything you want. So it's possible that similar parts can have wildly varying filenames only based on who created the file.

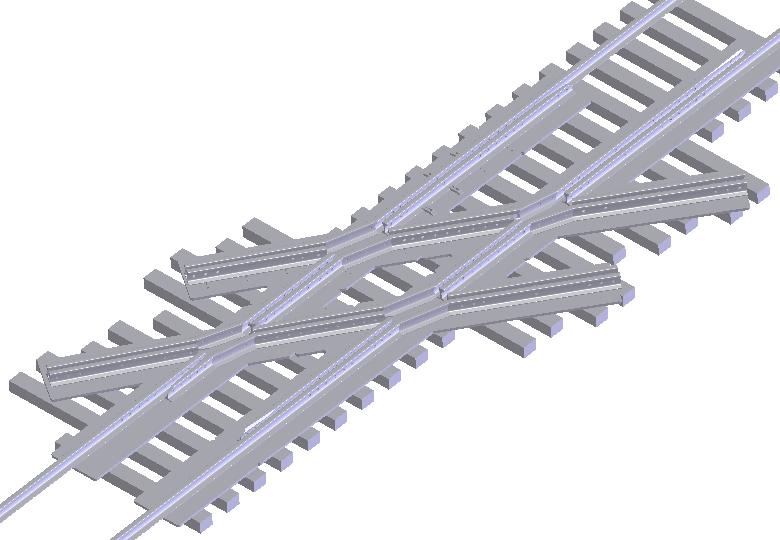

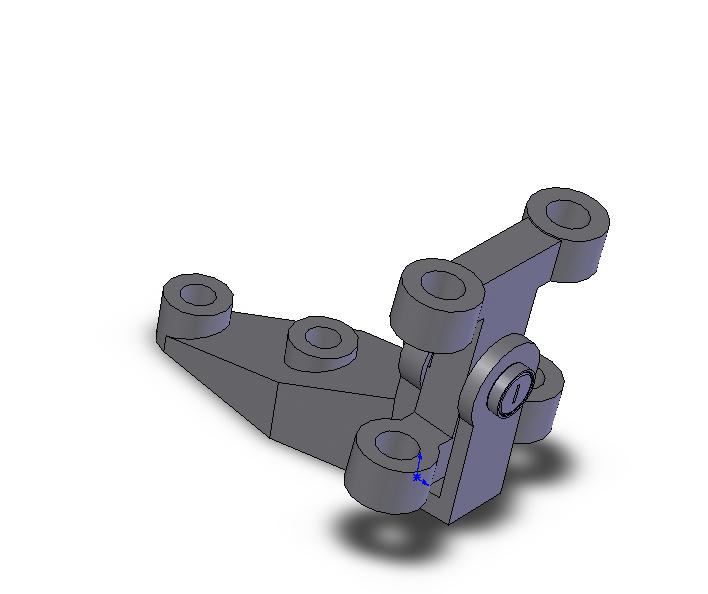

The need for proper document management is more acute than it ever was before. For manufacturing companies to remain competitive parts and assemblies need to be standardized and reused wherever possible. Even where the products are so called "one-of's" there is often room to standardize. Look at automotive assembly tooling and fixturing. At one point every fixture was "unique". The advent of standardized "NAAMS" tooling has allowed designers to reuse many components over and over again keeping the number of special parts to a minimum.

All manufacturing companies can benefit from this type of standardization. There are always parts that are used over and over again such as mounting brackets, limit switch mounts, drive housings, roller bearing mounts and so on. Much can even be accomplished even with only with a good stock of shims and nutplates in the engineering library. These items can easily be dragged and dropped into any assembly from a central part library.

PDM Systems

Production Data Management systems exist and are good at preventing different parts from having the same number. They also help with revision control making sure everybody only uses the latest revision of a part. They cannot always prevent new parts being uploaded to the drawing vault that are identical to existing parts but with different part numbers. They do work well with central drawing libraries of often reused parts.

The same old dilligent, detail oriented individual with a thorough knowledge of the entire engineering database is still a necessity. Now that person will likely have a PDM system at his or her command but so long as its done properly and used by the book, it should not matter if they use PDM, Excel, a Database, or an MRP system or a 3 ring binder.

Structured Bill of Material

Perhaps the most potent weapon that dilligent person needs to have is a structured bill of material in their arsenal. The structured bill is a single document that all designers use to create new projects. It simply summarizes what old assemblies are available for reuse so that duplication of part numbers and assemblies is kept to a minimum.

When a designer chooses a new part number for a new assembly, the old part numbers are there for review so that the designer can add new configurations to them, or modify them, or create something totally new.

The structured bill is not at all a fancy document. In its simplest form it could be just a word document. It adapts to changes in the engineering department by serving as a record for decsions to standardize on certain frames and assemblies and purchased parts. It can easily be added to and expanded and regularly distributed in its latest revision to all designers and draftsmen in the department.

MRP Systems

The MRP system holds out the best promise to assist the dilligent person because most MRP systems have sophisticated "where used" functions that allow you to search across multiple projects to find parts, or drawings that are used in multiple locations.